life cycle services of crushers

Crusher services - Metso

Life Cycle Services Get the most out of your crushing circuit. Whether you are looking to minimize downtime, increase capacity, lower your cost per ton, improve sustainability, or meet specific size-reduction requirements – Metso can support you.

Read More

Life cycle assessment of a rock crusher - ScienceDirect

2000.2.1 Nordberg, a capital equipment manufacturer, performed a Life Cycle Assessment (LCA) study on its rock crusher to aid in making decisions on product design

Read More

Stationary service solutions

Our proactive service solutions cover the entire lifecycle of your crushing and screening plant. Our highly trained, expert engineers deliver you the right parts and service

Read More

Understanding three different types of crusher

2018.3.15 Implementing a preventive maintenance program is the best method of keeping a crusher in good operating condition for a long period. Preventive maintenance will include scheduled checks,

Read More

Life Cycle Assessment of a Rock Crusher - ACEEE

2020.2.5 Life Cycle Assessment (LeA) is an analytical tool used to comprehensively quantify (and optionally to interpret) the material and energy flows (to and from the

Read More

Crushing - Metso

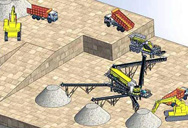

Metso in-pit crush and convey (IPCC) solutions provide an integrated solution consisting of crushing, conveying, and stacking equipment combined with IPCC planning and life cycle

Read More

What affects liner life?

Extending the life of liners in your cone crushers can significantly reduce maintenance costs and improve productivity, so its vital that any problems in this area are identified and

Read More

Crusher - an overview ScienceDirect Topics

Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size. They are classified as jaw, gyratory and cone crushers based

Read More

Stone Crushers: A Technical Review on Significant Part of

2022.5.14 These types of crushers generally find their applications in crushing of brittle rocks like quartz and ready mix concrete sites. The crushing process in these

Read More

Construction Working and Maintenance of Crushers for

2018.12.26 Crushers for Bulk Materials. Crushers and breakers are used to reduce size of mined and quarried material for further processing or to size suitable for the

Read More

Crushing - Metso

The crushers are built to perform with the lowest cost per ton, featuring a unique combination of crusher cavity design, crushing forces, reliability and safety. ... and stacking equipment combined with IPCC planning and life cycle services. Through the industry's strongest building blocks of team, technology and services, Metso is able to ...

Read More

life cycle services of crushers - restartpotapeni

life cycle services of crushers; Crusher services Outotec. From durable parts to comprehensive maintenance and optimization services to full Life Cycle Services Spare and wear parts for crushers Having the proper parts supply onhand is critical to your operations With decades of experience in designing, producing and supplying wear and

Read More

The benefits of Contender™ Series: Premium spares for non-Metso crushers

2024.3.25 These improvements lead to longer-lasting crushers that require less maintenance, enabling sites to maximize uptime and productivity. For instance, consider the spider bushing located at the top of the crusher. ... Having the option to wrap both wear and spare parts supply along with other maintenance services in a long-term Life Cycle

Read More

Nordberg® C Series™ jaw crushers - Metso

Nordberg® C Series™ jaw crushers are mainly used as primary crushers in aggregates production, mining operations and recycling applications. The product family consist of models of different sizes that are engineered to deliver the maximum productivity at the lowest operating costs. Uncompromised reliability. Pinned and bolted, non-welded ...

Read More

Mobile crushers and screens - rockprocessing.sandvik

To support our comprehensive range of mobile crushers and screens, we offer unrivalled aftermarket support, to help provide you with the necessary parts and service to keep your equipment running for longer. In our world, uptime and availability make all the difference. Genuine Sandvik spare and wear parts enable safer, easier maintenance and ...

Read More

The Complete Guide to Primary Crushing, Secondary

2023.2.28 Primary, secondary, and tertiary crushing are three stages in the comminution process that break down large rocks into smaller pieces of varying sizes. Each stage uses different types of crushers and has distinct advantages and disadvantages. This article provides a comprehensive guide to primary, secondary, and tertiary crushing.

Read More

Crushers - All crusher types for your reduction needs - Metso

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

Read More

life cycle services of crushers-Life Cycle Services far better

May 13, 2019 Life Cycle of a Private Foundation; Life Cycle of a Private Foundation Sample Organizing Documents Draft A Charter ... except that the corporation shall be authorized and empowered to pay reasonable compensation for services rendered and to make payments and distributions in furtherance of the purposes set forth in Article Third ...

Read More

Nordberg® GP Series™ cone crushers - Metso

Nordberg® GP Series™ cone crushers have been developed to crush feed materials into desired end products efficiently, reliably, and economically. Engineered for all rock types, these machines can be utilized as secondary, tertiary, and quaternary crushers in aggregates production plants and in mining operations. Long-term performance.

Read More

sbm/sbm life cycle crushers.md at master - sbm

You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

Read More

Cone crushers - for demanding crushing needs - Metso

Cone crushers are very suitable for size reduction and shaping in the downstream of a crushing circuit. They reduce the material in a crushing cavity by continuous compression between a fixed element (bowl liner) and a moving element (mantle). Cone crushers are equipped with a hydraulic setting adjustment system, which allows adjusting the ...

Read More

Stone Crushers: A Technical Review on Significant Part of

2022.5.14 2 Concept of Stone Crusher. Stone Crusher is a sort of pulverizer which is utilized to compress or break out assortment of enormous stones. It normally highlights a huge crushing rate and high return and is utilized as an essential equipment in primary, secondary, and tertiary stages of crushing.

Read More

What Are the Differences Between The 7 Types

2024.7.15 A high-quality hammer crusher can keep final material 100% passing a twenty mesh, fifty to sixty percent passing a fifty-mesh screen. Crusher hammers are high chrome content. The hammer service

Read More

Understanding Industrial Crushers: Types And Applications

2023.8.1 Gyratory crushers, invented by Charles Brown in 1877, are elegant tall devices that crush material between a conical fixed outer shell and a smaller conical inner shell that gyrates. As the inner cone rotates, it crushes the material against the outer shell, reducing it to smaller sizes. Gyratory crushers are unique in several ways.

Read More

Mobile crushers and screens - SRP

Mobile crushers and Screens. We offer a wide range of mobile crushers and screens, both tracked and wheeled, to help you process rock in the toughest conditions. This selection includes jaw crushers, impactors, cone crushers, screens and scalpers for quarrying, construction and rock excavation projects. Powerful, agile and fully mobile crushers.

Read More

Stationary HSI Impact Crushers, Horizontal Impact Crusher,

The all-new 700 series of Horizontal Shaft Sandvik impact crushers offers new levels of safety and efficiency. Developed to comply with new EU legislation, you can configure these smart, modular crushers to operate in a variety of applications in either primary or secondary crushing mode. The perfect HSI crusher for primary (feed sizes up to ...

Read More

Superior™ MKIII Series primary gyratory crushers - Metso

Primary gyratory crushers are the initial driving force for the entire mineral processing circuit. Metso's Superior™ MKIII primary gyratory crushers provide high throughput and less downtime to bring maximum efficiency to your operation. Contact our sales experts. Higher throughput. Increased speed, installed power and mechanical improvements.

Read More

Sandvik launches powerful secondary stage crusher

2017.3.7 The automation and control system offered as standard for Sandvik 500-series crushers ensures optimal capacity and reduction settings for the high-powered equipment. Las Vegas, US, 7 March 2017. For more information, contact: Magnus Holst Product Marketing Manager, Life Cycle Service, Crushing and Screening Sandvik Mining

Read More

Nordberg® HP6™ cone crusher - Metso

Less downtime, more confidence. Nordberg® HP6™ cone crusher delivers less downtime and increased operator confidence. Dual-acting hydraulic tramp-release cylinders are used to let the crusher pass tramp iron and to provide a large clearing stroke if needed. The double accumulator combination provides better reactivity of the hydraulic system.

Read More

Life Cycle of a Servlet - GeeksforGeeks

2021.10.19 There are three life cycle methods of a Servlet : init () service () destroy () Let’s look at each of these methods in details: init () method: The Servletit () method is called by the Servlet container to indicate that this Servlet instance is instantiated successfully and is about to put into service.

Read More

India Crushers Market (2024-2030) Trends, Outlook

The India crushers market is poised for significant growth, driven by various factors. One of the primary drivers is the rapid urbanization and the expanding construction industry in the country. Crushers play a crucial role in processing and recycling construction and demolition waste, contributing to sustainable construction practices.

Read More

Crusher wear parts - Metso

Reliable crusher spare parts enable stable production without unexpected downtime. Our offering of spare parts is available for all Metso crushers – from Nordberg® and Symons™ models to mobile and portable crushers.

Read More

QS332 Cone crusher - SRP

400 mm (16 in.) Capacity. 344 mtph (379 stph) Sandvik QS332 is a compact, robust mobile secondary cone crushing solution designed for versatility and ease of operation. Fitted with Sandvik CS430 "S" type gyratory cone crusher, it is capable of accepting large feed sizes whilst achieving high production capacities.

Read More

life cycle services of crushers - shortjana

magnetc separator: life cycle services of crushers. life cycle services of crushers guide to mobile equipment life cycle costing Crusher South Africa Joy Global Peru S.A.C. Mining equipment and services Life Cycle Management; Home. Polyurethane tension mats for longer life. 04/11/2022, 2:35 pm 04/11/2022 55. Events. Events. ... faster cycle ...

Read More

Nordberg® MP Series™ cone crushers - Metso

Nordberg® MP™ crushers bring cone crusher performance to a new level. They provide the highest crushing power for any cone crusher of similar size. Advanced crushing dynamics leads to more work per cycle. The MP™ crushers increase the power draw resulting in an increase in capacity, and a higher power-to-production ratio and energy efficiency.

Read More

Construction Working and Maintenance of Crushers for

2018.12.26 Generally gyratory crushers, jaw crushers, high speed double roll crushers, low speed sizers, impactors and hammer mills are used as primary crushers. In the secondary and subsequent stages, the material is further reduced and refined for proper size and shape, mostly based on specifications. Most secondary crushers are cone

Read More

Nordtrack™ mobile crushers - Metso

Track-mounted crushing plants. Features. Nordtrack™ mobile crushers are designed for asphalt recycling, concrete demolition and small scale aggregate production. They are ideal equipment when you work in short-term contracting jobs or are just starting your own operations. Contact our sales experts.

Read More

Our Range of Trio® Cone Crushers Weir

Trio® TC Series Cone Crushers. The Trio® TC Series cone crusher is the latest iteration of the live-shaft cone crusher. This design has been proven to perform in heavy-duty secondary and tertiary crushing applications being tough, reliable, simple to operate and easy to maintain. They are also effective for pebble crushing applications.

Read More

How it Works: Crushers, Grinding Mills and Pulverizers

2017.6.2 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl liner.Gyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface. As the gap

Read More

Rock Crushers, Stone Crushers, Screening and Crushing

200 kW. Capacity (by hour) 330 - 960 mtph (364 - 1,058 stph) Feed opening. 1,300 x 1,130 mm (51 x 45 in.) mm. Motor power. 160 kW (250 hp) Sandvik crushing and screening equipment. Unrivaled jaw crushers, cone crushers, gyratory crushers, impact crushers and more for mining and construction applications.

Read More

- تتبع الجوال الفك سحق النبات 100 Tph

- كتاب عن المواد المستخدمه في مساحيق الغسيل

- مصنع لتجهيز الجبس بالسودان

- صور من كسارة الكاولين في نيجيريا ساماك

- مصدر ماكينات التعدين

- مصنع كسارة حجري 200 طن في مصر

- منح العقد محطم

- مداد خط تولید

- محجر pozzolana في الإمارات العربية المتحدة

- آلة المحجر وبيع محطة كسارة في أستراليا

- قائمة كسارة الحجر تشغيل المصنع في ي

- گیاهان استخراج در پاکستان

- محاسبه نوار نقاله اینرسی کمربند

- كسارة مخروط جعل المعادن 42 50 بوصة

- محطم الجيل الحجر كسارة الحجر